Wood-Mizer Bandsaw BLADES are used in sawmills in almost every corner of the world, from Europe to Asia, Africa, and both Americas. These blades saw every type of wood – from hard tropical species to softwood from Europe. Wood-Mizer is a world-leading brand in the market of wood processing machinery. In Europe, Wood-Mizer has been operating for more than 30 years, and the name of Wood-Mizer is associated with high-quality band sawmills. There's a blade in the heart of every such machine that converts a log into valuable material for building unique sets of furniture, a large deck, or a charming cottage house.

Wood-Mizer offers bandsaw blades in over 100 configurations, based on different profiles, tooth settings, and steel grades. Thanks to these various blade characteristics, Wood-Mizer can supply the sawmillers with blades perfectly matching their needs. Wood-Mizer blades are manufactured under experienced and qualified workmen's supervision using top-quality European steel and utilizing the most advanced machine tools available for the industry today. The blade production is located at Wood-Mizer's factory in Poland, in the very heart of Europe.

The blade production process at Wood-Mizer European manufacturing center is certified according to the standards of ISO 9001:2015. Wood-Mizer blades must pass all strict quality checks at every production stage before they are allowed to be sent to market.

Steel Material Checks

The whole manufacturing process is controlled by a computerized system and an advanced internal lab that is responsible for ensuring only the best material is used. The material that fails control tests is sent back to the supplier and is not used further in the production process. Thanks to a unique marking on each blade, Wood-Mizer identifies the raw material used for production, the production date, and a person responsible for quality checks and controls.

From start to finish, Wood-Mizer uses the best equipment to manufacture sawmill blades. The approved raw steel is prepared and processed on highly efficient and specialized machines capable of continuous work and producing a product that passes additional quality checks.

Teeth hardening

In the next stages of production, the selected kinds of blades are induction hardened. In this process, every tooth of the blade is hardened to make it stronger and tougher. As a result, the blade can cut for a longer time, it's more resistant to abrasion, and it can cut with higher quality, especially in hard species of wood. Quality control at this production stage includes checking if the hardness of teeth meets the required standards.

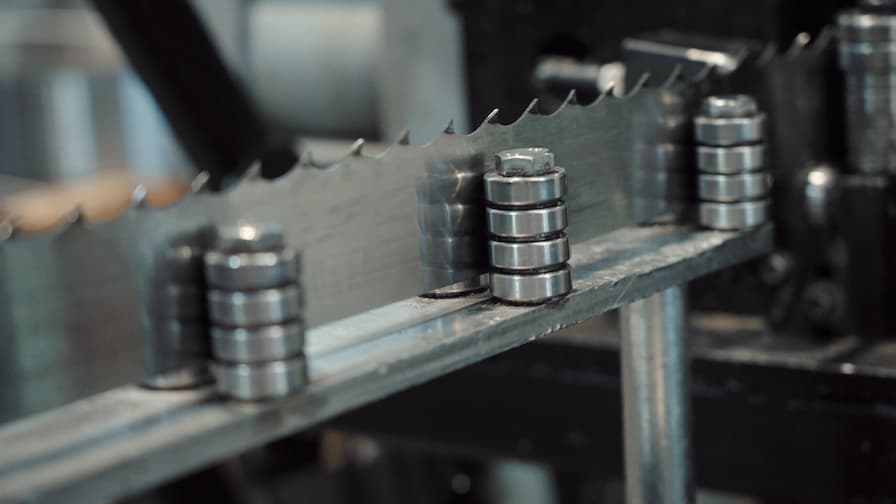

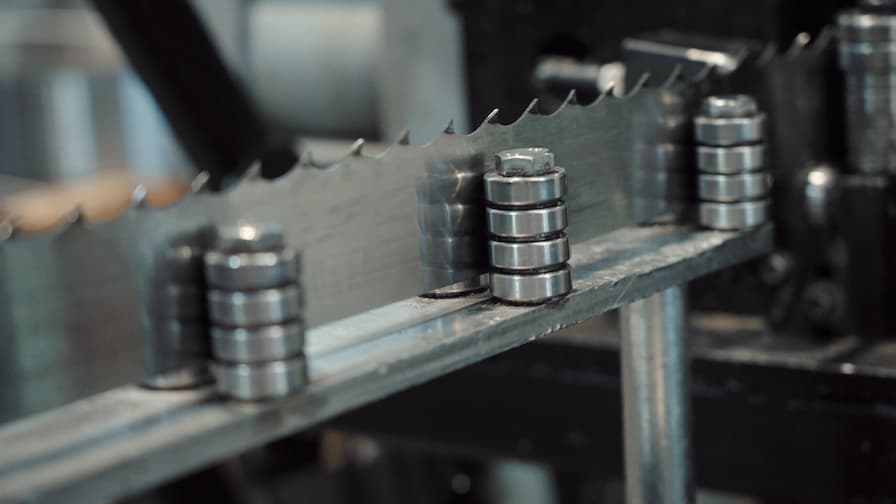

Blade Profile Making

Now, the blades are passed on for sharpening, setting, and blade-length cutting. Depending on the customer's order, Wood-Mizer cuts the material to the desired length. The process of sharpening and setting is essential in achieving the desired parameters of the blade. Thanks to sharpened and correctly set teeth, the blade can cut wood effectively for a long time. At Wood-Mizer, line operators continue to perform the various quality tests.

Welding

The machines utilized for both welding and grinding are very advanced and highly specialized. With expert knowledge and specialized equipment, Wood-Mizer produces a stable and robust weld on the blades. This precise and reliable weld is one of the main points that distinguish Wood-Mizer blades from other competitor products. After the welding operation, blades are properly ground in order to work smoothly and seamlessly in every type of wood.

Packaging and Shipping

Only the blades which have successfully passed all strict quality tests qualify to ship to the customer. We put them into branded boxes with the Wood-Mizer logo and label them with full product information – blade type, width and length of the blade, type of blade material, profile, raw material ID number, date of production, and QR code. Providing this information with every box of the blade helps to determine when the blade was produced, who checked its quality, and which material was used to make it. When Wood-Mizer blades leave the factory, they are ready to saw.

Wood-Mizer customers confirm that the original Wood-Mizer BLADES can guarantee high quality of cutting and extended lifetime, and all that - at a very affordable price. If you value professional and safe work, choose the original blades from Wood-Mizer!

***